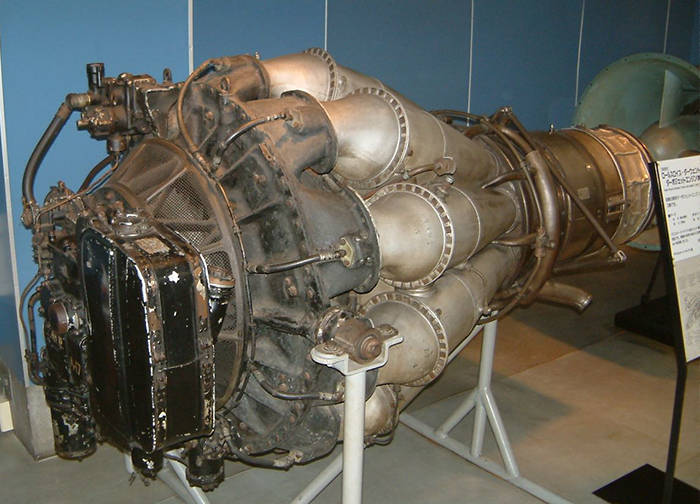

Derwent

The Rolls-Royce RB.37 Derwent is a 1940s British centrifugal compressor turbojet engine, the second Rolls-Royce jet engine to enter production. Essentially an improved version of the Rolls-Royce Welland, itself a renamed version of Frank Whittle's Power Jets W.2B, Rolls inherited the Derwent design from Rover when they took over their jet engine development in 1943. Performance over the Welland was somewhat increased and reliability dramatically improved, making the Derwent the chosen engine for the Gloster Meteor and many other post-World War II British jet designs.

The Derwent Mk.I entered production with 2,000 lbf (8.9 kN) of thrust. Mk.II, III and IV's followed, peaking at 2,400 lbf (10.7 kN) of thrust. The Derwent was the primary engine of all the early Meteors with the exception of the small number of Welland-equipped models which were quickly removed from service. The Mk.II was also modified with a cropped impeller (turbine unchanged)[4] and a reduction gearbox driving a five-bladed propeller. It was called the Rolls-Royce RB.50 Trent and was the first turboprop to fly. Two were installed in a Meteor I.

The Mark V used the basic Derwent design was also used to produce a larger 5,000 lbf (22.2 kN) thrust engine known as the Rolls-Royce Nene. The Nene was such an advance over the Derwent that Derwent development effectively ended. The Nene was, however, larger in diameter and so could not fit into the nacelles of the Meteor. The next Derwent version, the Derwent Mk.V, was instead produced by scaling down the new Nene to the diameter of the previous Derwent, specifically for use on the Meteor.

Several Derwents and Nenes were sold to the Soviet Union by the then Labour government, causing a major political row, as the Nene was the most powerful production turbojet in the world at the time. The Soviets promptly reverse engineered the Derwent V and produced their own unlicensed version, the Klimov RD-500. The Nene was reverse-engineered to form the propulsion unit for the famous MiG-15 jet fighter. The Derwent Mk.V was also used on the Canadian Avro Jetliner, but this was not put into production.

On 7 November 1945, a Meteor powered by the Derwent V set a world air speed record of 606 mph (975 km/h) TAS.

© . All rights reserved |

© . All rights reserved |